The ‘Erly Tour – Winter Projects

Almost as long as I’ve had Moon Shadow I have been investigating ways to lower my carbon footprint. One of the first things I did was to install solar panels to charge the domestic batteries so that I wouldn’t have to rely on plugging into mains electricity when in a marina. It also meant that I could spend extended periods away from marinas which really suited my ethos.

There are two other sources of pollution on the boat – the propane cooker and the diesel engine.

The first one I wanted to tackle was to replace the engine with an electric motor. I’d been investigating various options but all the systems that I looked at were hideously expensive. I knew I had to put together a DIY solution. I’d been following the YouTube channel “sailing Uma” and they had done a conversion using an old forklift motor. I didn’t want to go quite to that level but it definitely inspired me.

Then in late 2021, I came across a Canadian company called County Cape which supplies electric propulsion systems for DIY installers. This seemed like the ideal compromise. I contacted them and spoke to the owner, Brahm, and told him what I wanted to achieve and, together, we came up with a system.

It was to be a 72 volt, 10 kilowatt motor powered by a 78.96 volt 280 Amp Hour Lithium battery (24 3.29 volt LiFePo4 cells connected in series). A deal was struck and I ordered the system which Brahm would have delivered to Croabh Haven so that it would be there when I returned from my Christmas break.

So it was that when I returned to Scotland at the beginning of March ’22 there was a stack of boxes waiting for me.

The first thing I had to do was to remove the old diesel engine so I arranged with the marina to have Moon Shadow lifted out of the water. At the time the weather was unseasonably warm and sunny but by the time I got the boat lifted out, we were back into a typical Scottish winter which was to cause me a few headaches later.

In order to remove the diesel, I had to first remove the companionway steps. Of course, as is always the case when working on boats, in In order to do one job a number of other jobs need to be done first. In this case, I had to remove the trim from the corners of the companionway before the steps would slide out and, naturally, they had been installed before everything was varnished so I had to cut through the varnish with a Stanley knife first…

Once everything was out of the way I set about disconnecting everything which turned out to be somewhat easier than I had envisioned. After that I had the marina guys bring over the crane and with an engine hoist attached to the hook we hoisted the old thing out.

Once the engine was out it was swiftly followed by the old fuel tank, the exhaust system and all the control cables. I then set about cleaning the whole thing up, sealing up the exhaust outlet (although I decided to keep the spigot in place just in case I ever want to refit a diesel) and removing the through hull for the raw water inlet.

Then came the task of installing the new electric motor.

I was quite fortunate that there was a half bulkhead through which the diesel engine, or, more precisely, the gearbox used to pass and I planned to use this to attach the motor mounting plate to. I had a local engineer cut out a 6mm steel plate for me but the only problem was that I somehow had to mount it at an angle to match the prop shaft angle. I then had an amazing stroke of luck. Laying around the yard were a number of wooden wedges that they used to wedge the boat props in place and these turned out to be exactly the right angle!

After a little bit of adjustment, I had the motor lined up and the prop shaft slid straight into the coupling (which I’d repurposed from the old gearbox).

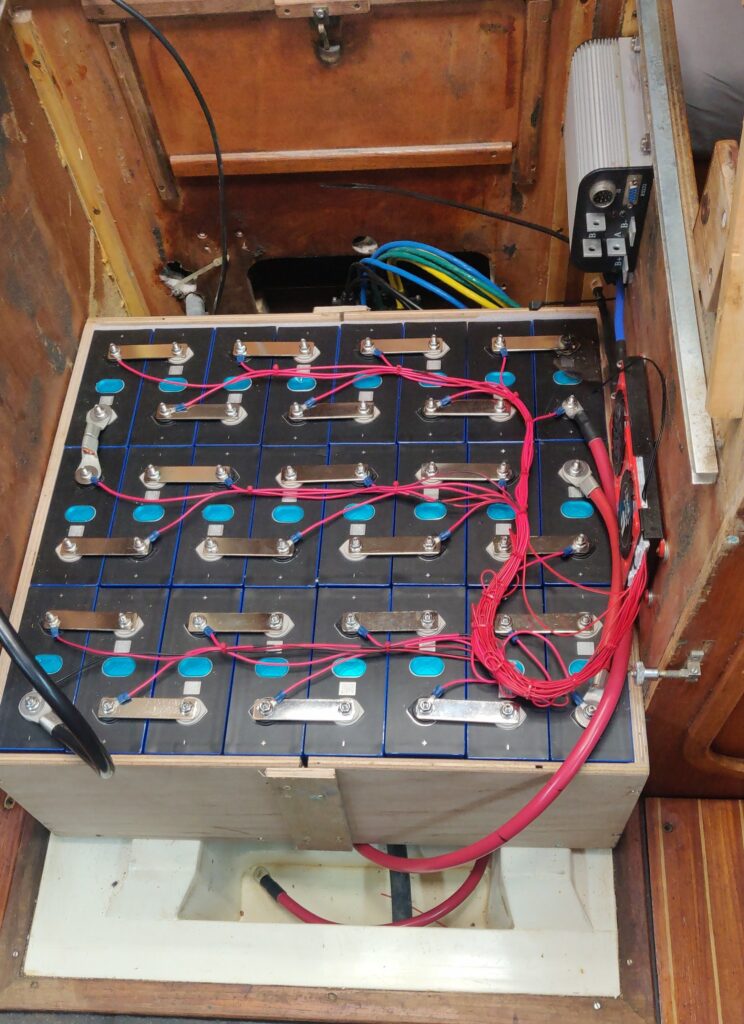

I had my brother, who is a cabinet maker, make a plywood box to house the batteries but, to counter my previous stroke of luck, I’d incorrectly measured the size of the batteries by just a millimetre so the lovely box was about seven millimetres too narrow – aarrgghh! I had to cut the box in half and join the pieces together with some offcuts.

There are twenty four batteries connected in series. Each battery is 3.29 volts and 280 Ah giving a total of a fraction under 79 volts or 22.1 KWh. With my 10 Kw motor that gave a theoretical battery life of just over two hours – more about that later.

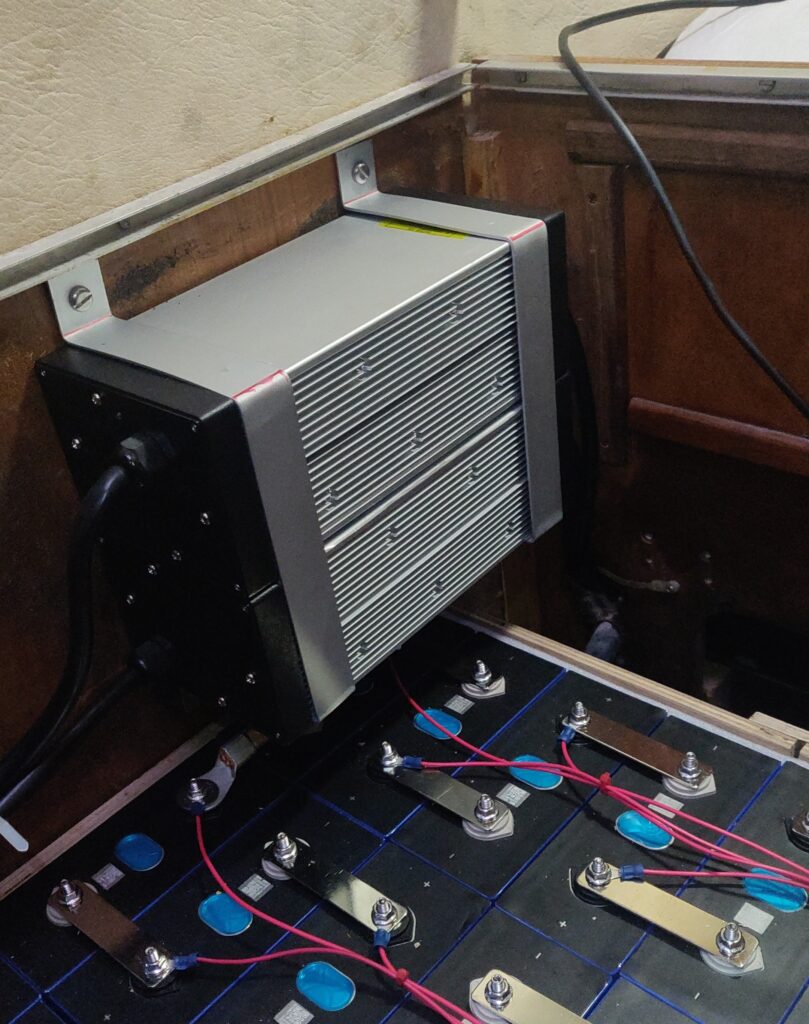

After the batteries, I fitted the Kelly Controls controller, the BMS, and the 2.8Kw shore power charger. Once everything was in I had the slightly terrifying job of wiring it all up. I needn’t have worried as it was actually pretty straightforward and I only had one minor welding incident because I stupidly connected the battery negative lead first – it should have been the last thing I did.

Once everything was wired up I had to program the controller which was relatively straightforward but, not really knowing what setting I’d need I set everything quite conservatively. Then it was the moment of truth – would it work? Well, that turned out to be somewhat of an anti-climax as it purred away nicely! I only had to make one adjustment which was to reverse the motor as it was running the wrong way for the prop so forward was backward and backward was forward. It was just a simple matter of connecting the reverse wire to ground and everything worked as it should.

But how would it work in practice? I’d tested it out whilst tied to the marina and it seemed to be providing plenty of thrust so there was nothing for it but to let go of the lines and take her out!

The first thing that became apparent was that the controller programming would need to be adjusted to give a faster (motor) acceleration. I’d set this parameter too conservatively and it just didn’t pick up quickly enough which gave me a slightly heart-stopping moment when I came a bit close to another boat as I was reversing out of the slip.

Once out of the marina I headed towards Oban, about fifteen miles north. I motored for about half an hour and the battery monitor showed only a one percent drop in battery capacity. That boded well for motoring range.

I then set the Genoa and turned off the motor and sailed north to Oban. Upon entering the Sound of Kerrera I was faced with a seventeen knot wind on the nose. The sound is quite narrow and relatively busy so tacking would be quite troublesome so I furled the sail and turned on the motor.

I’d been motoring for about twenty minutes and just as I got to the narrowest part of the sound, where the small ferry goes back and forth, the motor stopped! I quickly unfurled the genoa and started sailing again. Checking the battery monitor I could see that there was over 90% battery so it couldn’t be that. I wasn’t very far from the marina in Oban so I could sail there and if necessary get a tow into the berth. However, about fifteen minutes later I tried the motor again and it started. So, I was able to motor to the marina and get tied up safely. Upon investigation, it transpired that the controller had overheated. I’d need to arrange some cooling. I went into town the following day and bought a 12-volt fan and mounted it behind the companionway steps to draw more air through the motor bay.

So the first outing under electric propulsion had been a success – notwithstanding the overheating, hopefully, that is now sorted.

The Kit

- Motor: Golden Motor brushless DC 10 KW

- Controller: Kelly Controls KEB72101

- BMS: Daly 24S 72V 150A

- Battery: Docan Power, 3.29V 280Ah, LiFePo4 x24

- Mains charger: YZPower-600, 1400w x2

- All equipment supplied by County Cape